We sell and rent out tools for beveling and cutting of pipes to industries as pipeline builders, decomissioning, nuclear power plants, offshore, shipyards, industrial plumbers and others.

See our product pages for detailed descriptions and overview over our tools.

Orbital welding!

The industry that faces this area as its daily challenge knows what the beveling joint means for the final result. Tri Tool has invested considerable resources in producing machines that can maintain the necessary tolerances, while maintaining productivity and reliability. For smaller pipes in the range 1" (25,4mm) to 36" (914,4mm), our machines in the 200 and 300 series are well suited.

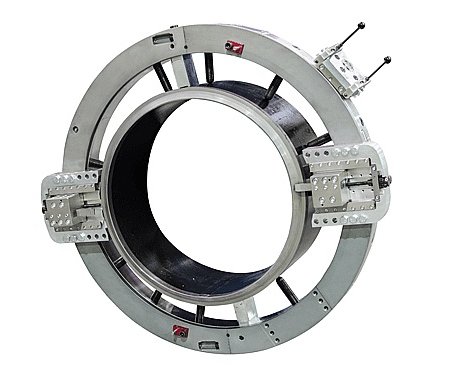

Pipe Clamps!

Our Pipe Clamps are manufactured with the industry in mind that wants to weld the bottom string directly towards "backing", in addition, Clamsene centres the pipes perfectly

Special products!

Tri Tool also manufactures special machines and equipment according to the customer's wishes and needs. Please get in touch, we will always be ready to take on challenges facing the industry.

History!

Tri Tool was introduced to Europe in 1987 in connection with the jack-up on the Ekofisk oilfield.

It turned out that Ekofisk sank, and it became necessary to carry out a controlled jack-up. Tri Tool undertook the work of developing cutting/beveling machines, so-called "Clamshells" that could manage to cut and grout 42" (1066.80mm) pipes with 3" (76.20mm) wall thickness in one and the same operation. The machines and equipment used on this pioneering project have since been further developed and are today characterized as our 600SB and 600RBL machines.

On the Norwegian offshore sector, it became necessary to move from thick-walled carbon steel pipes to high-alloy materials with high corrosion resistance, at the same time as wall thickness and specific gravity became important criteria. In the process of developing lighter oil platforms and installations, industry was forced to use other types of materials such as titanium, Super Duplex, etc. This placed new demands on cold cutting and welding joints with a much greater emphasis on tolerances. In this development from the early 1990s and until today, Tri Tool has been an important partner for the oil and gas industry, and together we have developed machines and equipment that are well known all over the world.

PFM Machines!

For machining pipes in the range from 6” (152,4mm) to 56" (1422.4mm), we have developed so-called PFM machines for mass production of welding joints with tolerances of 0.10mm. Previous methods that could take up to several hours can now be done in seconds.

Flange Face Machines!

Our Flange Face machine type 442F, working in the range from 14" (355.6) to 73" (1854.2mm), is considered by many to be the machine that is both best and easiest to use, when it comes to turning flanges.

Copyright © Med enerett